Mine cart machine is used to realize the function of pushing and pulling the mine cart in short distance. It is widely used in wellhead truck yard, underground truck yard, gang-tur...

Overview of CXC-I Pin Gear pusher

Mine cart machine is used to realize the function of pushing and pulling the mine cart in short distance. It is widely used in wellhead truck yard, underground truck yard, gang-turning truck yard and drift.

Our company is one of the most comprehensive wheelbarrow equipment manufacturers in China at present, producing chain wheelbarrow, pin gear type wheelbarrow, line type wheelbarrow machine (including rail line type wheelbarrow machine) three different structure of the cart machine.

CXC-I pin - tooth cart advantages

1, a hydraulic station as the power source of the whole set of equipment, the previous pneumatic, electric or electric, electric hydraulic push rod mixed use into a single hydraulic drive.

2. The hydraulic station adopts double motor and double pump hydraulic source system, with one pump working and the other standby, making the system safe and reliable.

3. Drive the whole set of equipment with one motor, and when the equipment does not move, the motor is in the state of empty load operation, which saves power, reduces production and operation costs, and extends the life of the equipment.

4, the hydraulic cylinder as the power actuator of the equipment, so that the structure of the equipment can be more compact, soft action, small impact, easy maintenance.

5. The trolley is driven by the hydraulic motor with low speed and large torque, which does not need the deceleration mechanism. It is easy to install and arrange, which reduces the investment. Transmission system rotation inertia is small, can start full load, and do not need to stop when reversing.

6. Control the load and speed of the equipment by adjusting the system pressure and flow rate according to the actual situation on site, and have the function of overload automatic protection.

CXC pin tooth pusher centralized hydraulic system has compact structure, fast action response and stable and reliable operation. It is an ideal power system for mine operation equipment and can be widely used in coal mines and metallurgical mines.

Trolley electromechanical control system and power system

A variety of signals and instrument indication Windows are set on the electric control operation desk of the electric control system for pushing cart, which can monitor the running state of the whole pushing cart system in real time and issue control instructions to control the orderly running of pushing cart and other related equipment. The electronic control system of flameproof type vehicle stop is composed of three parts: mine intrinsically safe operation table, KXJ127 mine flameproof and intrinsically safe electric control box, and position sensor. All components have coal safety mark certificate and explosion-proof qualification certificate. There are two kinds of power system: electro-hydraulic power system and motor-reducer power system. The electro-hydraulic power system USES explosion-proof motor as the power source, and adopts flameproof hydraulic station to drive the hydraulic motor to run, so as to realize the forward and backward of the trolley. The motor - reducer power system is driven by mine explosion-proof motor, and adopts the motor - reducer transmission mechanism to drive the sprocket operation, so as to realize the forward and backward of the cart.

Compared with the power system of the motor-reducer, the electro-hydraulic power system has the following performance advantages: (1) The hydraulic system adopts the dual hydraulic source structure of two machines and two pumps, of which one is working and the other is standby, and the other can be put into use immediately after the failure of one, which ensures the continuous operation of the cart machine for a long time. (2) The speed regulation and pressure regulation function of the hydraulic system make the thrust and speed of the cart be adjustable, and the hydraulic overflow protection function fully protects the mechanical structure of the cart, so that the mechanical mechanism will not be damaged in the event of mechanical clamping. (3) The hydraulic system has the functions of pressure protection, liquid level alarm, filter blockage alarm and unloading, and can be equipped with the hydraulic system heating function or hydraulic system cooling function according to the external environment, to ensure the long-term stable work of the system.

Structure and working principle of CXC-I pin - tooth pusher

The main equipment of the centralized hydraulic system of CXC-I pin gear trolley includes: hydraulic station, operation table (electric control box), trolley support, active trolley, driven trolley, push claw, buffer device, etc.

The pressure and flow rate of the hydraulic station can be adjusted, the system pressure is set by the electromagnetic relief valve, and its operating speed can be set according to the requirements of the cage turning time the best value. Electromagnetic relief valve has automatic unloading function, when the system is not working, electromagnetic relief valve unloading, hydraulic pump no-load operation.

Hydraulic station and equipment working organs (motor) USES the high pressure hose connection, each corresponding electromagnetic directional valve and its control equipment, oil in and out of the mouth in the same side as the integrated block, when integrated block below a row of tubing for the flowline, above a row of tubing for return pipe, cart equipment into the loading job status, up close, pusher retreat, tipper began to work. Each high pressure hose is marked with length, not wrong, not opposite.

Use and maintenance of CXC-I pin gear pusher

1. Working Conditions:

Oil temperature range: 0℃ -- 60℃.

The highest temperature for continuous operation should not exceed 60℃, and the oil temperature should be frequently checked during use. Touch and check the thermometer with your hand. If the oil temperature rises abnormally, it may be caused by the following circumstances:

When the oil quality deteriorates, the resistance increases;

Electromagnetic relief valve is damaged and the system cannot be unloaded;

Internal block, pressure loss is too large;

It is recommended to use YB-N46 anti-wear hydraulic oil (GB2512-81), and the oil cleanliness should meet iso4406/1986 (18/14) standard.

2. The hydraulic oil in the oil tank should be kept at the normal oil level, and it should be injected from the oil filling port of the air filter. After the first use of the hydraulic station, the oil tank should be cleaned once and the hydraulic oil and filter elements should be replaced one month after the formal operation.

3. The return oil filter of the hydraulic station is equipped with differential pressure flood generator. When the pointer on the flood generator enters the red zone, the filter should be shut down in time, and the filter should be opened, cleaned or replaced.

4. The oil suction filter of the hydraulic pump is provided with a pressure difference flood generator. When the pointer on the flood generator enters the red area, the filter element should be replaced timely; If the blockage, easy to make the pump cavitation phenomenon, causing damage to the pump.

5. In case of system failure, it is strictly prohibited to check and adjust in the working state or under pressure.

6. When the equipment is not used for maintenance, the motor should be stopped and the power switch should be turned off.

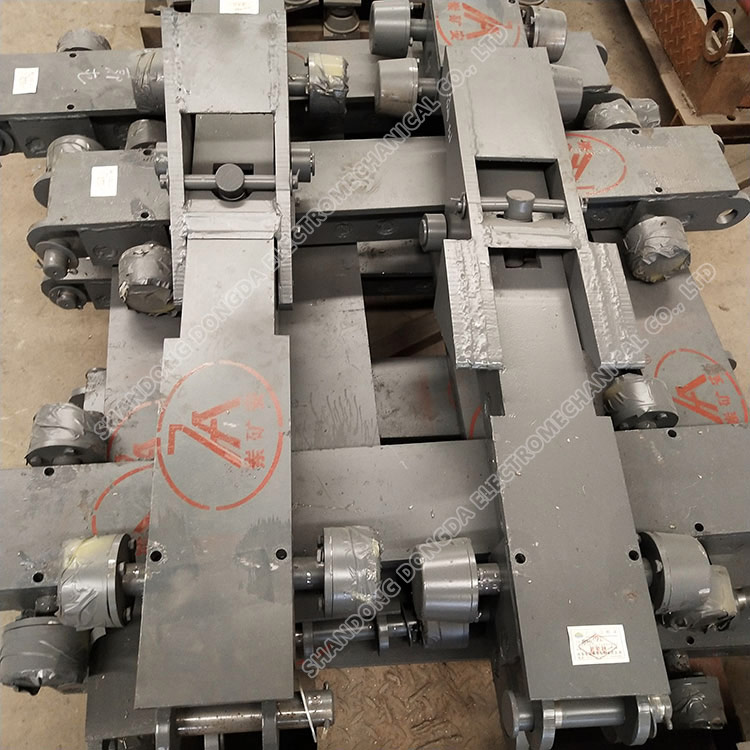

Physical picture of CXC-I pin tooth pusher